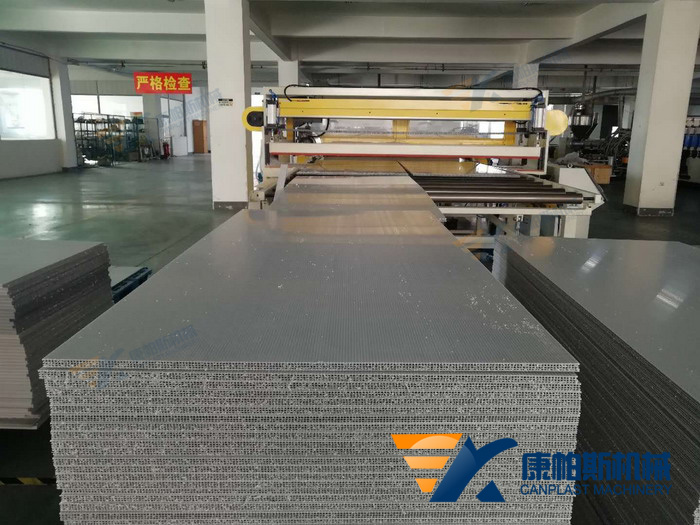

PP one mold double out building template production line

Hollow Construction Board extrusion machine,PP Construction Board production machine

1,After continuous innovation and testing, produced PP one mold double out building template production line on the basis of the traditional 915mm single production line,that not only could meet the demand of large output and low energy,but also could ensure the stability of product's quality.

Performance & characteristics:

1. three layer coextrusion production line:

1.1A extruder: JWS150/35 (motor power 132KW)

1.2B extruder: JWS80/30 (motor 37KW)

1.3 Production line output:900pcs /day

2. three layer composite distributor:

2.1 through two extruders co extrusion, the upper and lower surfaces of the products can be evenly distributed.

2.2 the composite thickness can be adjusted flexibly according to the needs

3. multi-layer lattice mold:

3.1 mold mandrel adopts the latest three tier grid structure.

3.2 double channel design is adopted to ensure the stability of material extrusion.

3.3 the upper and lower die lips can be fine-tuning to better control the product surface thickness.

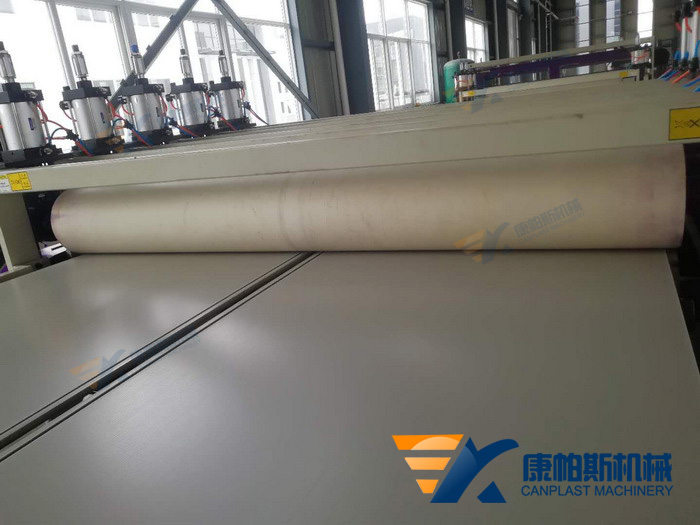

4. three grade type board:

4.1 adopting the three stage design, it can meet product stability in high speed production.

4.2 the cooling channel design of the innovative cooling plate can effectively take away the product setting temperature.

4.3 uniform vacuum tank design ensures uniform internal structure and stable performance.

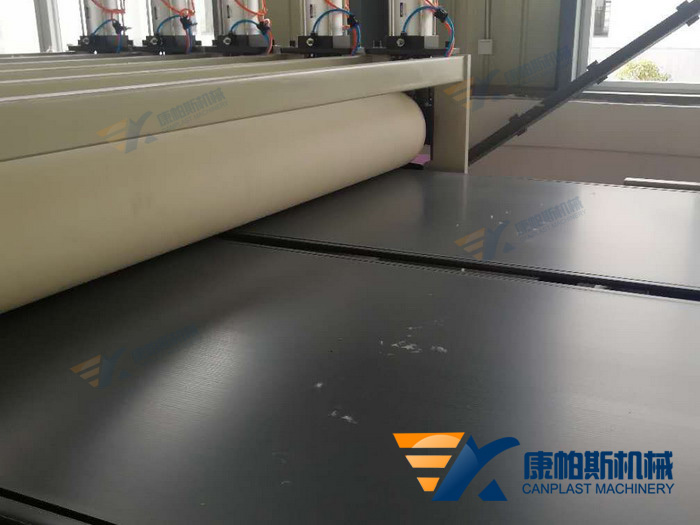

5. combined tractor

5.1 through the design of two stage combined tractor, the flatness of the product can be effectively controlled.

5.2, we can reduce the unqualified products generated by each boot.

6. automatic fixed length cutting machine

6.1 special cutting design can minimize the edge of the product.

6.2 for PP raw materials, the sawtooth is improved, and sawdust will not be bonded when cutting.

6.3 the automatic length fixing function of the product is convenient for people to operate, and the cutting accuracy is high.

PP one mold double out building template production line Main technical parameter

|

extruder model |

SJ-120/33 |

SJ-150/33 |

SJ-120/33 SJ-65/33 |

SJ-150/36 SJ-65/33 |

|

Screw L/D ratio (L/D) |

33:1 |

33:1 |

33:1 |

33:1 |

|

|

|

33:1 |

33:1 |

|

|

Product width (mm) |

915-1220 |

915-1220 |

915-1220 |

915-1220 |

|

Product thickness (mm) |

14-16

|

14-16

|

14-16

|

14-16

|

|

Main motor power (kw) |

110 |

160 |

37-132 |

37-160 |

|

Max. extrusion capacity (kg/h) |

300 |

500 |

400 |

600-700 |

Contact: mina

Phone: 13668861858

Tel: 13668861858

Email: kangpas@163.com

Add: Pingcheng East Road,Jiaozhou,Qingdao